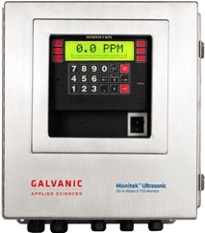

Monitek Ultrasonic™ Oil in Water & Total Suspended Solids

OIL IN WATER (OIW) AND SUSPENDED SOLIDS ANALYSER SYSTEM

When it comes to monitoring samples that have high suspended solids, are opaque in colour etc, traditional optical-based technologies are just not able to offer reliable results. This is where our Galvanic, acoustic based products come in. These sensors deliver rugged, reliable, real-time results to optimise your processes, and assure consistent quality and regulatory compliance. The Monitek family of turbidity and total suspended solid (TSS) monitors are ideal for applications that require detecting suspended solids in samples that typically coat sensors, particles in opaque liquids, and oil in water.

Monitek Introduction

Rapid Return on Investment

Key Applications

|

|

Measurement Certainty

|

The Monitek UltraSonic multi-sensor controller delivers unparalleled flexibility and economical operation:

|

|

SummaryMonitek’s two-component systems include modular, fit-for-purpose probes to pair with a controller. The monitors employ the principle of ultrasonic reflection for measurement, where an emitted ultrasonic pulse is reflected by the particles in a return “echo,” which is back-scattered and transformed into an electronic signal. The system detects, evaluates, and then displays the signal as a precise measurement value. Various sensor configurations allow for installation into process pipes, tanks, or open channels.

To request a brochure or for further product information, please contact us |